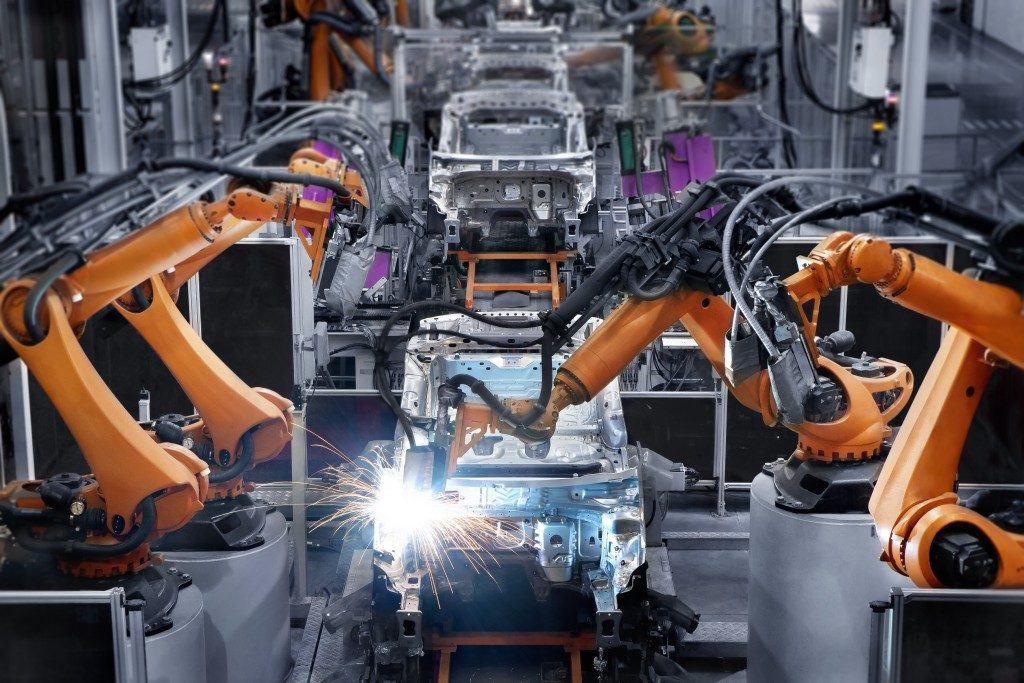

The modern automotive industry is a highly competitive business environment. If your business is facing challenges on multiple fronts — from consumers demanding a bigger eco-friendly impact on the environment and wanting increasingly sophisticated features, to keeping suppliers costs down — you often need to streamline your processes and become more efficient in order to successfully address all concerns. Doing so can be a complex undertaking — here are five areas you can start working on.

Upgrade specific equipment

While it can be tempting to address efficiency concerns by simply investing more money in the latest equipment, the smart move would be to identify the upgrades with the biggest impact. You’ll definitely boost productivity if you buy a five-axis machining centre for north of $100,000, but you could also see major improvements from investing a fraction of that amount in a new oil transfer pump with continuous operating capabilities. You can run the numbers on Excel to estimate the return on investment (ROI) for a purchase, or consult with fellow industry professionals who’ve already upgraded to the equipment you have in mind.

Assess and streamline workflows

If you like to take a big picture approach, employing a technique such as value stream mapping can immediately identify specific areas which need attention. Toyota pioneered this method to streamline its processes and eliminate wasteful, non-value adding activities while en route to establishing itself as a global brand and industry leader. Once you’ve noted these pain points, you can bring the respective supervisors on board and let them tackle the task of redesigning specific workflows and monitoring for improvements.

Supply chain consistency

In recent years, political uncertainty, volatile oil prices, and an unpredictable environmental future have all contributed to disruptions in the supply chain for many industries. Manufacturers relying heavily on a single supplier can suffer costly delays or quality issues. Maintain a close relationship with multiple suppliers, and subscribe to any applicable networks and databases, so that you can be alert to potential issues in the supply chain and make quick adjustments to avoid a significant impact.

Reduce scrap and recalls

Many analysts consider efficiency only in terms of output over input, but any manufacturer with hands-on experience knows that you also have to factor in the cost of losses to product flaws or recalls. Certain improvements to your quality assurance process, such as autonomous machine vision systems, can greatly reduce the risk of faulty parts making it further down the production line. The data from these systems is comprehensive and lets you carry out a detailed analysis of a defect’s origin, which is useful not only for process improvement but also to safeguard against claims.

Invest in people

Advances in technology can bring innovation to the automotive industry, but that also comes with an element of disruption. Employees at every level must be able to adapt; over the decades, we’ve seen outsourcing, automation, and software solutions take over various tasks in nearly every industry.

Invest in your people, giving them the training that will help them stay on top of the latest developments in the business and to be able to take on the complex, value-adding tasks which remain. In return, you’ll have a loyal and skilled workforce infused with your company values, avoiding the costs of frequently recruiting and onboarding new workers.

Becoming more efficient as a manufacturer isn’t easy, but if you can successfully identify the key areas for improvement, your approach will pay dividends in the long term.